Information about FRIES Kunststofftechnik GmbH

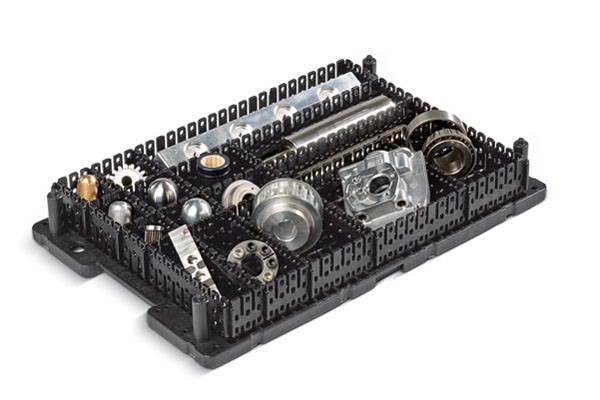

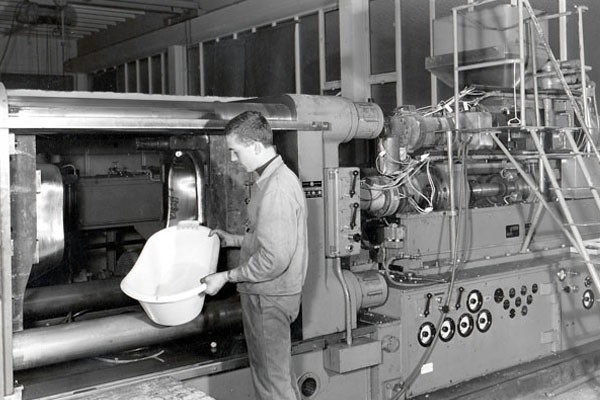

FRIES is a specialist in plastics processing and focuses on the development and production of high-quality plastic products.

The business areas in which the plastics processing company is active are subdivided into industrial packaging, catering dishwasher racks, workpiece carriers, and industrial baskets, as well as technical moulded parts.

Production takes place exclusively at the Sulz site. Around 5,000 tonnes of plastic are processed here every year. The export rate for the products is 85%. Customers are supplied in more than 50 countries worldwide.

FRIES Kunststofftechnik is a third generation family business with headquarters in Sulz, Austria. The company currently employs 250 people, 6 of whom are apprentices.

The plastics technology company has a strong network of locations and partners throughout Europe.

Facts

Turnover in 2023: €41 Mio.

(FRIES Group)

Export to 50 countries worldwide

Export rate of 85%

250 employees, 6 apprentices

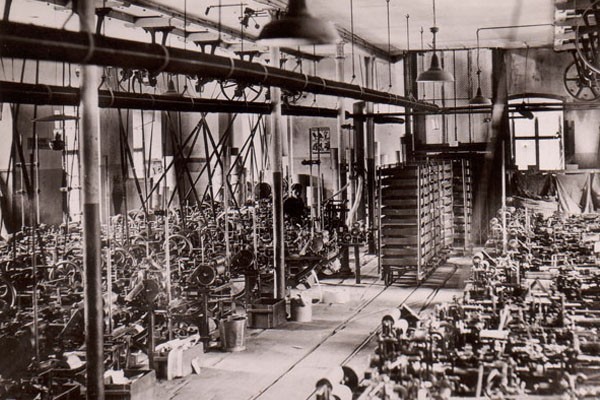

The history of FRIES