References Industrial Baskets and Workpiece Carrier Systems

Our customers’ trust in our products grows from project to project.

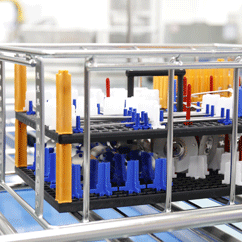

We are an innovative supplier of all-in-one systems for industrial parts cleaning – tech-rack, techtray and tech-rack variogrid have proven to be effective in all processes – from cleaning through transport to storage.

Personalized support, high quality and durability of our products are our distinctive characteristics, just as our long-time experience and in-depth technical expertise. Through continuity in collaboration and our sustained interest in the success of our customers, we are able to jointly share in our success.

HAAG-STREIT AG, Koeniz (CH)

The leading manufacturer of slit lamps relies on the tech-rack variogrid workpiece carrier during the entire process from the lathe to assembly. The workpiece carriers are loaded on the lathe and cleaned in the chamber system. The focus is on maximum particle and surface cleanliness. The workpiece carriers are then transported in Euroboxes for assembly.

Video on how to use the tech-rack variogrid workpiece carrier system

SENSOR COMPANY (CH)

Workpiece carrier systems tech-rack variogrid are used in the production of sensor technology from the rotation and milling center to storage. The clear identification ensures that the workpiece carrier system is placed with the right divisions in storage. The rotation and milling center produces automatically overnight, thanks to 48 different workpiece carrier systems fitted by the robot.

Video on how to use the tech-rack variogrid workpiece carrier system

SCHNEEBERGER AG, Roggwil (CH)

For specialists in linear technology, the techtray workpiece carriers are used from the lathe through cleaning to final packaging. In addition to a high level of cleanliness, the workpieces are optimally protected during the processes in the entire factory area. This saves costs for intermediate packaging. The included marking ensures that the workpiece carrier is available at the workplace with the correct compartment divisions.

COMVAT, Haag (CH)

The workpiece carrier system tech-rack variogrid is used for the entire process from the lathe to storage as well as assembly. This way, the workpiece carrier systems are fitted at the lathe and then cleaned in a fully-automated ultrasonic cleaner with 7 baths. Cleaning is performed in an ISO8 cleanroom environment and the focus is on film and optical cleanliness (vacuum suitability). After that, the workpiece carrier systems are stacked in Euro containers for storage and future assembly.

FRENCKEN MECHATRONICS B.V., Eindhoven (NL)

Frencken develops, builds and manufactures individual components comissioned by customers, as well as complete machines and systems for the areas of medicine and research. Its customers include companies such as ASML, Philips Medical Systems, Bruker, and Thermo Fisher Scientific. Development and manufacturing for the hi-tech sector also means meeting top cleaning requirements. Frencken works with the latest system technologies, which includes the tech-rack variogrid system. The flexible workpiece carrier system ensures optimal cleaning results, offers top protection for delicate surfaces and enables safe transport of components.

ALUMINIUM PROCESSOR (A)

The tech-rack custom cleaning basket meets the high requirements of the Austrian aluminium processing company. The cleaning baskets are used in the automated feed to the cleaning system. The components are optimally rinsed here and clean, residue-free surfaces are thereby guaranteed. The tech-rack custom cleaning basket is used during the entire internal and external logistics chain.